In the competitive landscape of global manufacturing, choosing the right plastic compound is critical. At Mascom Global, we proudly supply Vietnam PA glassfiber Compound, engineered for maximum performance in sectors like automotive, electrical, and mechanical engineering.

What is Vietnam PA Glassfiber Compound ?

Vietnam PA glassfiber Compound is a reinforced thermoplastic made from polyamide (PA)—more commonly known as nylon—blended with glass fibers in ratios typically ranging from 15% to 50%. This blend significantly enhances the base material’s strength, heat resistance, and rigidity, making it ideal for high-load applications.

PA is inherently tough, but the addition of glass fiber transforms it into a material capable of outperforming standard plastics in extreme industrial conditions. It’s widely used in parts like engine covers, electrical connectors, industrial gears, and housings that require stability and durability under thermal and mechanical stress.

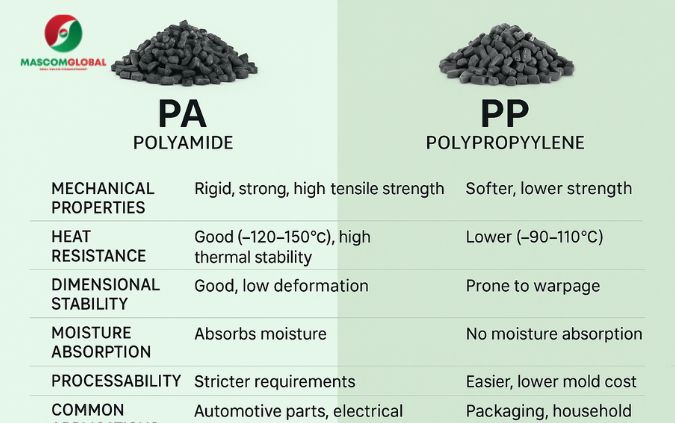

Vietnam PA glassfiber Compound vs. PP Glassfiber Compounds: Key Differences That Matter

While both PA and PP can be reinforced with glass fibers to improve their properties, PA (Polyamide) compounds deliver superior mechanical and thermal characteristics compared to PP (Polypropylene).

1. Mechanical Strength

- PA glassfiber compounds exhibit higher tensile strength and stiffness.

- Ideal for applications where mechanical load is critical.

2. Heat Resistance

- PA performs better under high temperatures (up to 120°C+), while PP has a lower heat deflection temperature.

- Suitable for under-the-hood automotive parts.

3. Dimensional Stability

- PA has low moisture expansion, maintaining tight tolerances.

- PP is more susceptible to warping and dimensional shifts.

4. Application Scope

- PA is used in gears, connectors, structural parts.

- PP is more common in less-demanding uses like casings or covers.

Learn more about PP glassfiber compound and how it compares in detail here.

Why Choose Vietnam PA Glassfiber Compound from Mascom Global?

With decades of expertise and robust sourcing, Mascom Global delivers Vietnam PA glassfiber Compound that meets global standards and client expectations.

Competitive Pricing

Vietnam offers favorable labor costs and material availability, making our PA compounds highly cost-effective without compromising performance.

High-Quality Resin and Additives

We use premium polyamide base resins and glass fibers, ensuring consistency and superior mechanical attributes.

Customizable Formulations

Our R&D team tailors formulations to meet your exact strength, thermal, and processing requirements.

Regulatory Compliance

All our compounds comply with RoHS, REACH, and other international safety standards.

Global Logistics Support

We offer stable supply chains and flexible shipping options to help international buyers streamline sourcing.

Typical Applications of Vietnam PA Glassfiber Compound

Thanks to its exceptional thermal stability, mechanical strength, and dimensional accuracy, Vietnam PA glassfiber Compound is trusted across multiple industries for critical functional parts. Let’s explore its role in greater detail:

Automotive

The automotive sector demands materials that can perform reliably under heat, mechanical vibration, and corrosive fluids. PA glassfiber compound fulfills these requirements:

- Engine Covers & Cylinder Head Covers: These components must endure elevated temperatures and oil exposure. PA GF maintains shape and strength without deformation or cracking, even in confined engine bays.

- Air Intake Manifolds: The compound’s resistance to continuous airflow at high temperatures and its sealing ability makes it ideal for air-intake systems.

- Radiator End Tanks & Thermostat Housings: With superior heat and chemical resistance, PA GF extends product life in cooling systems.

- Structural Brackets & Mounts: Its high modulus and fatigue resistance allow it to replace metal in parts like pedal brackets and HVAC support frames—reducing overall vehicle weight and fuel consumption.

Why it matters: The use of PA GF in under-the-hood components contributes to lighter, more fuel-efficient cars, helping manufacturers meet global emission standards.

Electrical & Electronics

In environments where fire safety, electrical insulation, and dimensional precision are non-negotiable, PA GF compounds are a preferred material:

- Connectors & Terminal Blocks: These parts require tight tolerances and heat resistance. PA GF minimizes warpage during soldering and provides excellent electrical insulation.

- Circuit Breaker Housings & Switch Gears: The material resists tracking and arcing, which helps maintain reliability in high-voltage applications.

- Cable Glands & Enclosures: With robust impact resistance and chemical inertness, PA GF ensures long-term protection of sensitive wiring in industrial or outdoor settings.

Why it matters: The compound’s UL-certified flame retardant grades help manufacturers meet international electrical safety standards, including UL 94 V-0 and IEC 60695.

Consumer & Industrial Goods

In power tools, appliances, and industrial machinery, durability and dimensional consistency are key. PA glassfiber compounds play a vital role in parts that are frequently exposed to vibration, heat, and mechanical stress:

- Power Tool Housings & Gear Components: The compound withstands repeated impact, high torque, and heat from motors—extending tool lifespan.

- Fasteners, Bushings, & Brackets: With excellent fatigue resistance, PA GF replaces metal in light-duty structural parts without sacrificing performance.

- Home Appliance Components (e.g., washing machine gears, vacuum impellers): PA GF ensures resistance to hot water, cleaning agents, and rotational wear.

✅ Why it matters: Replacing metal with PA GF can reduce noise, weight, and production costs, while simplifying manufacturing through injection molding.

Advantages of Using Vietnam PA Glassfiber Compound

Using Vietnam PA glassfiber Compound offers both performance and procurement benefits:

- Enhanced strength: Withstands mechanical stress better than non-reinforced resins.

- Thermal stability: Maintains performance under prolonged heat exposure.

- Lightweight: Offers metal-replacement potential in certain components.

- Corrosion resistance: Suitable for chemically aggressive environments.

- Processable by injection molding: Easy to form into complex geometries.

Processing and Handling Tips

To maximize the performance of PA glassfiber compound, follow these best practices:

- Pre-drying: Ensure resin is properly dried (typically 80°C for 4–6 hours) to prevent hydrolysis.

- Mold temperature: Recommended 80°C or higher for best surface quality.

- Screw and barrel design: Use wear-resistant alloys to handle the abrasive nature of glass fibers.

Why Global Importers Trust Mascom Global

Mascom Global has a proven record in delivering value-added plastic resins to global clients, especially in the U.S. market. Our commitment to quality, logistics reliability, and customer service has made us a trusted partner in international trade.

- Multi-industry supply experience

- English-speaking support team

- On-time shipping & documentation support

- Transparent pricing and bulk order advantages

Final Thoughts

If your application demands toughness, heat resistance, and dimensional accuracy, Vietnam PA glassfiber Compound is the smart material choice. At Mascom Global, we don’t just provide products—we provide tailored solutions backed by technical expertise and logistical strength.

Ready to boost your performance and optimize your supply chain?

Contact Mascom Global today and let us help you source high-performance PA compounds with confidence.

📩 Contact Information – PVC Compound For Wire And Cable Vietnam

We have different additives for your application. If you have any need, please don’t hesitate to contact with us to have the best offer. Thank you!

📞Phone: (+84) 326 169 955

✉ Gmail: info@mascomglobal.com

📍Address: Tien Tien Industrial, Quang Tien Commune, Hoa Binh, Vietnam

My Dinh Plaza 2 Building, 02 Nguyen Hoang Str., Nam Tu Liem Dist., Hanoi, Vietnam

📍Facebook: Mascom Global