Blog

Nylon 66 (PA66): The High-Performance Engineering Thermoplastic

Nylon 66, also widely known by its technical name Polyamide 66 (PA66), is one of the most significant and versatile engineering thermoplastics in the world. First patented by DuPont in 1937 and introduced commercially in 1939, PA66 has since become a staple in demanding industrial applications, offering a superior balance of strength, heat resistance, and durability.

As a high-performance material, Nylon 66 is distinct from Nylon 6 (PA6) due to its unique molecular structure and resulting properties. It is an opaque, light yellow crystalline polymer that finds extensive use across the automotive, electrical and electronics (E&E), industrial machinery, and textile industries.

The Chemistry Behind the Strength

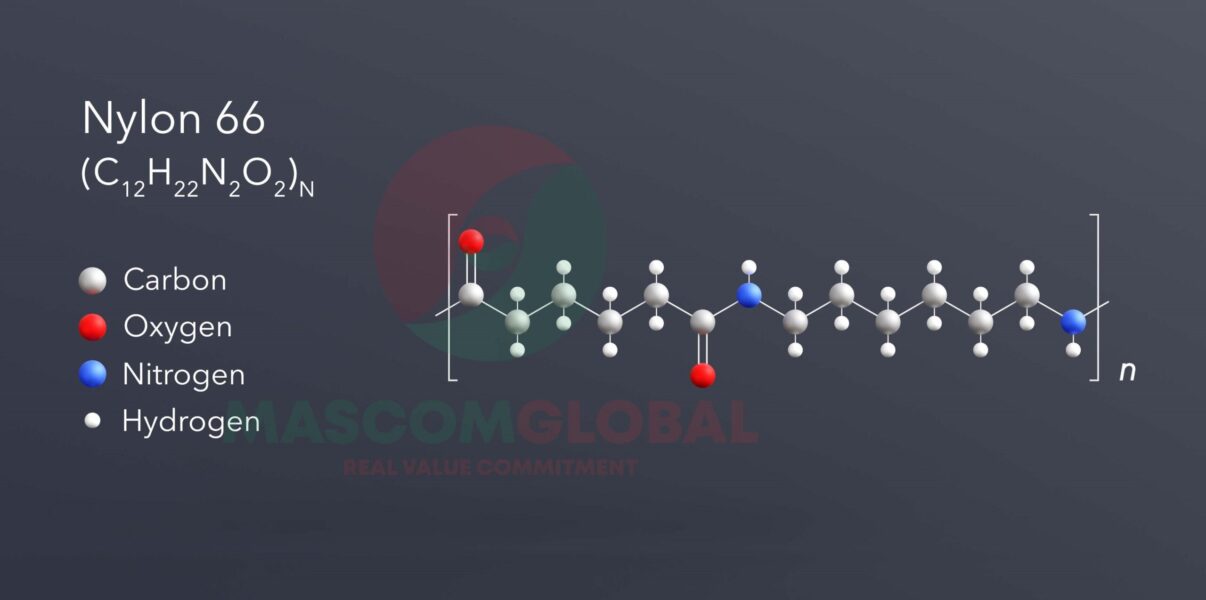

The “66” in its name is a direct reference to its chemical composition and synthesis process. Nylon 66 is produced through a polycondensation reaction between two monomers, each containing exactly six carbon atoms: hexamethylenediamine and adipic acid.

The reaction forms long polymer chains linked by strong amide bonds. The highly symmetrical and regular arrangement of these chains allows for a high degree of crystallization and strong hydrogen bonding between the polymer chains. This compact molecular structure is the secret behind PA66’s superior mechanical strength and thermal stability compared to many other nylons, including PA6.

Key Properties and Benefits

Nylon 66 boasts a range of properties that make it a preferred material for high-stress applications:

- Exceptional Mechanical Strength and Stiffness: PA66 exhibits high tensile strength and modulus, making it strong and durable, suitable for load-bearing applications.

- High Thermal Resistance: It has a high melting point, typically around 260-270°C, and can withstand continuous operating temperatures up to 85-120°C, and short-term exposure to even higher temperatures. This makes it ideal for “under-the-hood” automotive parts.

- Excellent Abrasion and Wear Resistance: PA66 has outstanding resistance to

friction and wear, making it a reliable material for moving parts like gears and bearings.

- Good Chemical Resistance: It offers robust resistance to a wide range of chemicals, including oils, fuels, greases, and many solvents, though it can be attacked by strong acids and bases.

- Low Moisture Absorption (Compared to PA6): While all nylons absorb some moisture, PA66 absorbs less than PA6, contributing to better dimensional stability and performance in humid environments.

- Impact Resistance: It offers good overall toughness and impact strength.

These properties can be further enhanced by incorporating additives and reinforcing agents such as glass fiber, carbon fiber, or mineral fillers, increasing stiffness and impact resistance even further.

Diverse Industrial Applications

The robust nature of Nylon 66 has led to its widespread adoption across numerous demanding sectors.

Automotive Industry

The automotive sector is a major consumer of PA66, largely due to the material’s ability to replace heavier metal parts, thereby reducing vehicle weight and improving fuel efficiency and emissions. Applications include:

- Engine Compartment Components: Radiator end tanks, air intake manifolds, engine covers, and oil pans.

- Safety Features: Components in airbag systems and seat belt mechanisms rely on the high strength and durability of PA66 fibers and resins.

- Exterior and Interior Parts: Handles, grilles, wheel covers, and various structural parts.

Electrical and Electronics (E&E)

PA66’s excellent electrical insulation properties and thermal stability make it a safe and reliable choice for E&E components. Common uses include:

- Connectors and Switches: High-voltage connectors for electric vehicles, terminal blocks, plugs, and sockets.

- Casings: Circuit breaker housings and electronic device shells.

- Cable Management: Durable cable ties and wire insulation.

Industrial Machinery and Engineering

The low friction coefficient and high wear resistance of PA66 make it ideal for mechanical components that experience constant movement and stress. Applications range from:

- Moving Parts: Gears, bearings, rollers, pulleys, and bushings.

- Conveying Systems: Components in conveyor belts and material handling systems.

- Structural Elements: Various machine parts and fastenings where durability is paramount.

Textiles and Consumer Goods

In fiber form, Nylon 66 offers superior strength and colorfastness. It is used extensively in:

- Apparel and Outdoor Gear: Sportswear, swimwear, raincoats, and heavy-duty workwear.

- Home Furnishings: Carpets and upholstery fabrics.

- Durable Goods: High-quality luggage, backpacks, and sporting equipment like tennis racket strings.

Mascom Global’s Commitment to Quality

At Mascom Global, we recognize the critical role high-quality PA66 plays in modern manufacturing. We provide specialized masterbatch and compound solutions designed to optimize the performance of PA66 products. Our commitment to quality and innovation ensures that manufacturers can achieve superior results in their applications, whether for enhancing UV stability, achieving precise coloration, or improving mechanical properties for highly demanding end-uses. Our tailor-made formulations help customers reduce production costs, improve processing efficiency, and maintain a stable, high-quality output.