In the world of manufacturing and engineering, gaskets play a vital role in creating sealed connections, preventing the leakage of liquids and gases. However, choosing the right material is a major challenge. That’s when flexible PVC compound emerges as an optimal solution, offering superior sealing performance for industrial applications.

What is Flexible PVC Compound for Gaskets?

Flexible PVC compound for gaskets is a type of synthetic polymer material, produced by blending polyvinyl chloride (PVC) with plasticizers, stabilizers, and special additives. This mixture creates a soft, flexible, and highly elastic plastic, ideal for manufacturing gaskets.

Thanks to a precise blending process, this material can be customized to meet strict requirements for hardness, color, and environmental resistance. Mascom Global, with its long-standing experience, always ensures the highest quality for its products.

You can refer to the articles on Mascom Global’s advanced production technology and quality control processes to understand more about us.

Core Benefits of Flexible PVC Compound for Gaskets

1. Outstanding Flexibility—Ensuring Optimal Elasticity for All Gasket Types

Flexible PVC compound is increasingly asserting its important role in many fields thanks to its outstanding application benefits. The first advantage is its high flexibility, a property created by its unique molecular structure. This allows the material to bend, stretch, or compress without cracking or breaking. As a result, products made from flexible PVC offer superior performance in:

Vibration and Noise Dampening: Effectively absorbs vibrations, contributing to a quieter environment.

Shock Absorption: Protects equipment and structures from strong impacts.

Soundproofing, Dust-proofing, and Water Resistance: Optimizes protection, keeping the interior clean and dry

2. Environmental Resistance – Suitable for Applications in Harsh Conditions

The versatility of flexible PVC compound in harsh environments makes it a popular choice in the construction, oil and gas, and electronics manufacturing industries. Products made from this compound not only serve their technical purpose well but also ensure long-term stability without frequent replacement, reducing maintenance costs and increasing usage value. This ensures that critical applications, such as industrial gaskets, maintain optimal performance.

Resistance to Moisture, Oil, and Chemicals: Flexible PVC does not deform, decompose, or degrade when exposed to water, oil, and many common chemicals. This is an extremely important factor for systems requiring a high degree of sealing in the industry.

Stable Thermal Resistance: The material maintains its shape over a wide temperature range, helping to minimize operational problems due to temperature fluctuations, ensuring continuous and stable operation.

UV and Oxidation Resistance: This ability helps maintain the physical properties of the product even when placed outdoors for a long time, resisting aging and degradation.

3. Key Role in Cost Optimization and Product Performance Improvement

Finally, the benefit of flexible PVC compound is its ability to optimize production costs and improve the operational efficiency of systems. Thanks to its toughness and ease of processing, this compound helps minimize material waste during manufacturing, reduces processing time, and saves labor.

Furthermore, flexible PVC compound is highly recyclable, contributing to a company’s sustainable development strategies. Using this environmentally friendly material not only helps reduce negative environmental impacts but also enhances the brand’s image in the eyes of modern consumers who increasingly prioritize green and safe products.

Performance Comparison: Flexible PVC vs Rubber

| Characteristic | PVC Compound | Rubber |

| Cost | More competitive, can reduce costs by 20-30% | Usually higher, depends on the type of rubber |

| Hardness (Shore A) | Wide range, can be adjusted from 50A to 90A | Wide range, but difficult to customize flexibly |

| Recyclability | 100% recyclable | Difficult to recycle, usually only partially recycled |

| Chemical Resistance | Good, resistant to many acids, alkalis, and oils | Varies by type, easily aged by oil |

| Durability | Good abrasion and impact resistance | Good abrasion resistance, but prone to tearing/ripping |

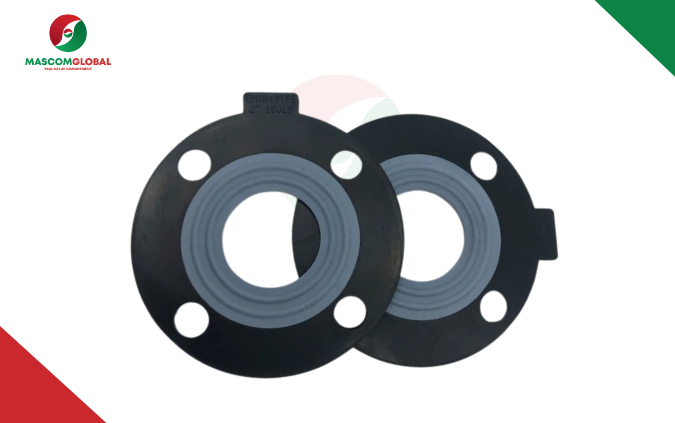

Practical Applications of Flexible PVC Compound for Gaskets in Industries

Flexible PVC compound is becoming the leading choice for gaskets in many industries thanks to its durability, environmental resistance, and superior flexibility. The use of this material helps improve efficiency and system stability and reduce maintenance and repair costs.

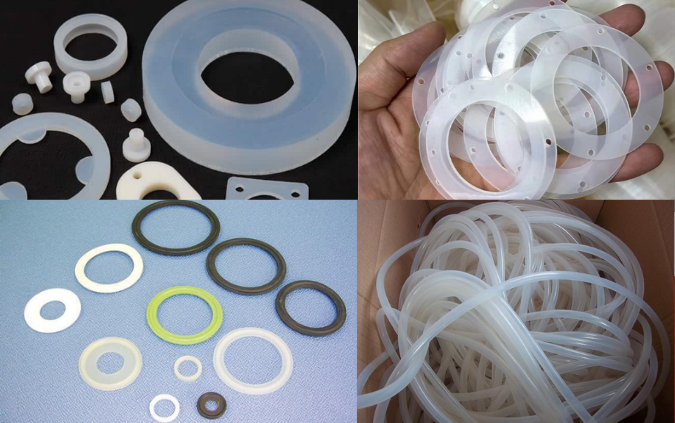

Automotive and Mechanical Industries: Ensuring Safety and Precision In the automotive industry, flexible PVC gaskets are a key factor in preventing gas or fluid leaks in fluid systems. With their ability to withstand pressure, temperature fluctuations, and chemicals, they ensure the quality and safety of gas, oil, and fuel systems.

Food and Medical Industries: Safe and Meeting Strict Standards Gaskets from flexible PVC compound strictly meet health safety standards; they are non-toxic and do not contain banned phthalates. They are widely used in packaging equipment, food machinery, and medical containers, ensuring hygiene, safety, and high precision.

Chemical and Energy Industries: Withstanding Harsh Environments In the chemical, energy, and wastewater treatment industries, flexible PVC gaskets demonstrate superior chemical and high-temperature resistance, maintaining airtightness and preventing leaks. In particular, their UV resistance helps extend the product’s lifespan, saving significant operating costs.

Contact Information

Contact Information

We have different additives for your application. If you have any need, please don’t hesitate to contact with us to have the best offer. Thank you!

Phone: (+84) 326 169 955

Phone: (+84) 326 169 955

Gmail: info@mascomglobal.com

Gmail: info@mascomglobal.com

Address: Tien Tien Industrial, Quang Tien Commune, Hoa Binh, Vietnam

Address: Tien Tien Industrial, Quang Tien Commune, Hoa Binh, Vietnam

My Dinh Plaza 2 Building, 02 Nguyen Hoang Str., Nam Tu Liem Dist., Hanoi, Vietnam

Facebook: Mascom Global

Facebook: Mascom Global