Blog

What is PP Film? Applications of Filler Masterbatch in PP Film Production

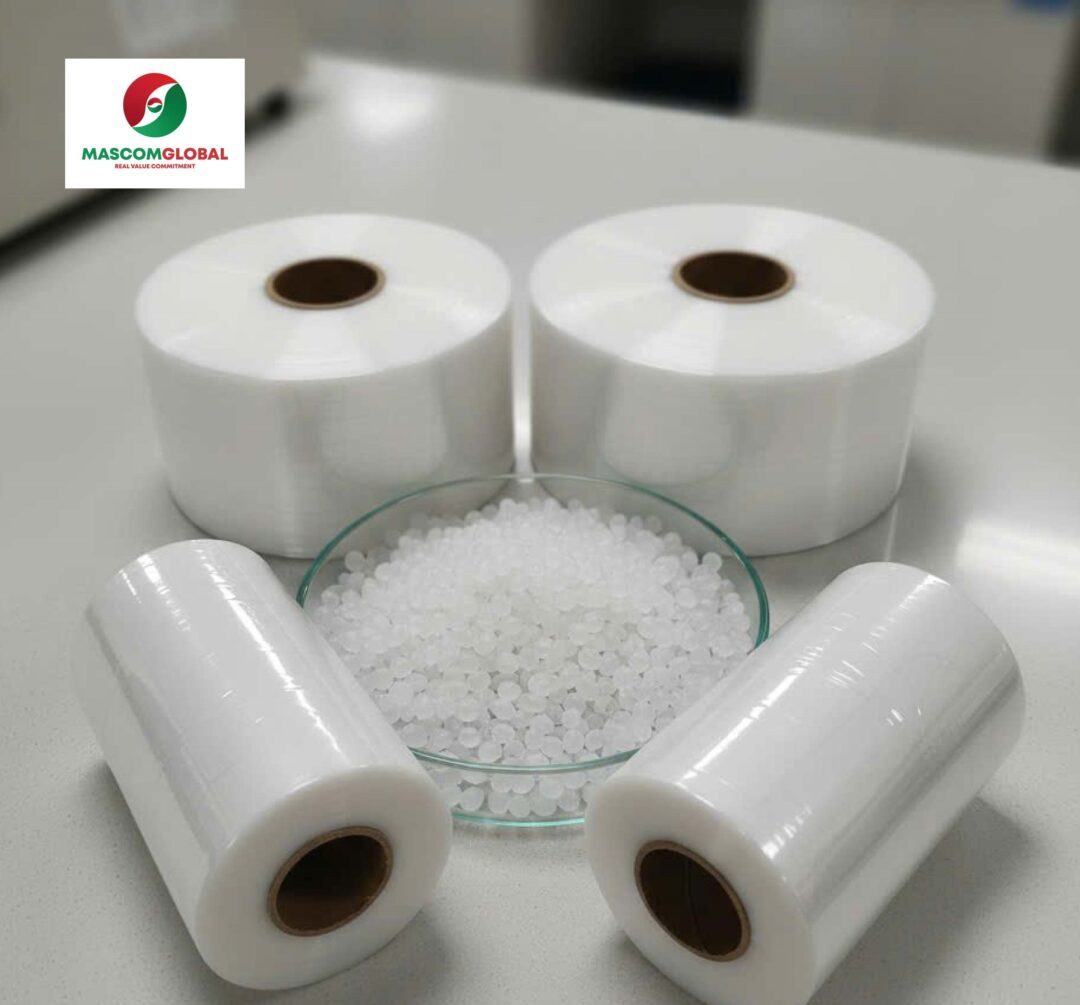

In the flexible packaging industry, PP film (Polypropylene film) is one of the most common and valuable plastic films due to its excellent mechanical strength, heat resistance, and high transparency. PP film is widely used in various fields such as food packaging, laminated films, woven packaging, and other industrial applications. Besides the main raw material of virgin PP resin, manufacturers often add Filler Masterbatch to optimize costs, improve properties, and enhance production efficiency.

This article explains what PP film is, its key characteristics, and why Filler Masterbatch has become a preferred solution in modern PP film production.

1. What is PP Film?

PP film is a plastic film made from polypropylene resin through blown film extrusion or cast film processes. The types of PP used for film production typically include:

- PP Homo-polymer: High stiffness, used for films requiring tensile strength.

- PP Random Copolymer: Better transparency and flexibility.

- PP Block Copolymer: High impact resistance, less common for thin films.

Key Features of PP Film

PP film is widely chosen due to the following advantages:

- High transparency, suitable for packaging that needs product visibility.

- Good tensile strength and stiffness, resistant to pulling forces during packaging.

- Heat resistance, typically 100–120°C.

- Food-safe and non-toxic, suitable for food packaging.

- Moisture barrier properties, ideal for dry food storage.

Additionally, PP film has good tear resistance, a glossy surface, and is easy to print on.

2. PP Film Production Process

The production process of PP film (especially blown film) includes the following steps:

- Material Mixing: PP resin + color masterbatch + additives + filler.

- Melting: Raw materials are melted in an extruder.

- Film Blowing: Molten plastic is inflated into a bubble.

- Cooling & Thickness Adjustment: Thickness controlled by pull-down speed and air volume.

- Calendering / Folding / Winding: Final film is rolled into coils.

In the formulation, Filler Masterbatch plays a crucial role in cost optimization and improving film properties.

3. What is Filler Masterbatch?

Filler Masterbatch is a compounded plastic additive made from:

- Calcium carbonate (CaCO₃), Talc, or Barium sulfate

- PP carrier resin

- Dispersing agents

Filler masterbatch is widely used in PP and PE film production due to its:

- Low cost

- Processing stability

- Ability to increase stiffness and improve film surface quality

4. Applications of Filler Masterbatch in PP Film Production

Filler Masterbatch not only reduces production costs but also provides significant technical benefits.

4.1. Reducing Production Costs

This is the main reason PP film manufacturers use filler:

- CaCO₃ is much cheaper than virgin PP.

- Replacing 10–40% of PP with filler significantly reduces raw material costs.

- Lower production costs make products more competitive in the packaging market.

4.2. Increasing Film Stiffness and Strength

PP film tends to be soft and deformable when stretched. Filler, such as CaCO₃, helps:

- Increase stiffness

- Reduce shrinkage

- Improve load-bearing capacity

- Stabilize the film at high-speed production

As a result, the film is less prone to tearing, wrinkling, and maintains better dimensional stability.

4.3. Improving Processing Performance

Filler Masterbatch improves the stability of PP film blowing by:

- Faster cooling → film solidifies quickly

- Reducing melt fracture

- Stabilizing the bubble

- Reducing sticking caused by high melt temperature

This is especially useful for ultra-thin films below 20–25 microns.

4.4. Enhancing Opacity & Printability

Depending on the intended application, some films require reduced transparency, for example:

- Industrial packaging

- Woven packaging

- Bags for parts and accessories

Filler can increase:

- Opacity

- Gloss

- Slightly rough surface → improves ink adhesion

PP films with filler are easier to print using flexographic or gravure printing due to a more consistent surface friction.

4.5. Environmentally Friendly & Recyclable

Filler Masterbatch is non-toxic and compatible with PP recycling:

- Produces minimal toxic gases when incinerated

- Reduces virgin polymer consumption → lowers CO₂ emissions

- Compatible with recycled PP

This helps manufacturers reduce costs and meet sustainable production requirements.

4.6. Increasing Production Efficiency

Factories using filler observe:

- Easier film release from dies

- Reduced gels and black spots

- Fewer filter clogs

- Smoother machine operation with fewer stoppages

- Uniform rolls with minimal wrinkles

All these contribute to higher output and lower operational costs.

5. Notes on Using Filler Masterbatch in PP Film

To achieve optimal results, manufacturers should consider:

- Choosing fillers with particle size of 1–3 microns

- Selecting the appropriate PP carrier resin (Homo / Random)

- Using a proper filler ratio (10–40%)

- Adding antioxidants, slip agents, or anti-block as needed

- Controlling filler moisture to avoid bubble defects

6. Conclusion

PP film is a vital material in the packaging industry due to its transparency, mechanical strength, and excellent processability. Filler Masterbatch not only reduces production costs but also significantly enhances product quality:

- Increases stiffness

- Stabilizes film blowing process

- Improves opacity and surface quality

- Boosts production efficiency

- Environmentally friendly and recyclable

Thanks to these benefits, filler masterbatch has become an indispensable solution in modern PP film production.