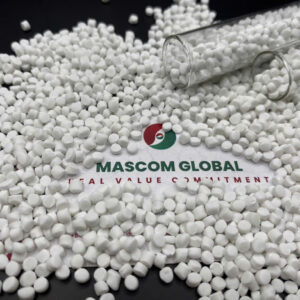

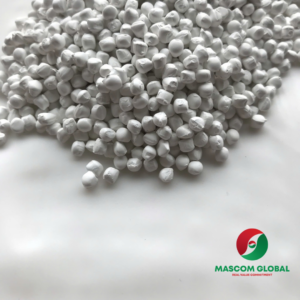

PE FILLER MASTERBATCH

PE Filler Masterbatch – What is it?

PE Filler Masterbatch is a blend of high-quality polyethylene (PE) resin, pure Calcium Carbonate (CaCO3) powder, and other additives. This combination is used to enhance the properties and cost-efficiency of plastic products. The ratio of these components is adjusted based on the specific requirements of different end-products to optimize performance.

Key Benefits of PE Filler Masterbatch:

1. Cost-Effectiveness:

Utilizing Calcium Carbonate (CaCO3) powder, which is less expensive than plastic resin, helps reduce overall production costs. This cost saving is significant for manufacturers, making it a valuable addition to the plastic production process.

2. End-Product Properties Enhancement:

Adding PE Filler Masterbatch to the plastic manufacturing process improves both the physical and mechanical properties of the final products. It also helps streamline production, making the process more efficient.

Safety and Certifications:

– Complies with the EU RoHS Directive, EN71-3, PAHs, PFOS/PFOA, REACH-SVHC

– Meets the national standard for water supply pipes (GS/10002.1-2006).

PE Filler Masterbatch is an effective solution for reducing costs while enhancing the performance of plastic products across various applications.

Reviews

There are no reviews yet.